Abstract

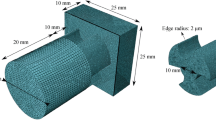

The present work is mainly focused on the macroscopic and microscopic examination of failed tungsten carbide (WC-Co) drill bits to find the root cause of the insert’s failure. Different failed WC-Co tool bits have been observed macroscopically and found that the inserts have failed due to shear-off, cracks, and gradual wear. The FE-SEM and AFM micrographs have been used to understand the different degradation and the tribocorrosion mechanisms of WC-Co inserts. Typical shape change mechanisms of individual WC grains have also been studied in detail with the help of FE-SEM micrographs, which have been influenced by the tribocorrosion in the presence of the mining environment. Ultrasonic cleaning method has been used to clean the inserts for the microscopic examinations. Various morphologies of fragmented WC grains have been examined to understand the shape change mechanisms of WC grains. The different electrode potential between the Co binder and the WC grains is the primary cause of the micro-galvanic form of corrosion. Hence, in the present study the wear and corrosion mechanisms of WC-Co insert along with the possible approaches to reduce the tribocorrosion have been discussed in detail. It was found that the proper understanding of tribocorrosion mechanisms is essential for the selection, development, and advancement of the suitable WC-Co tool materials.

modified by the addition of additives such as multi-carbides (VC).

Similar content being viewed by others

References

E. Lassner, W.-D. Schubert, E. Lassner, W.-D. Schubert, Tungsten in Hardmetals, In Tungsten, Springer, Boston, MA, (1999), p 321–363.

P.K. Katiyar, A Comprehensive Review on Synergy Effect Between Corrosion and Wear of Cemented Tungsten Carbide Tool Bits: A Mechanistic Approach, Int. J. Refract. Met. Hard Mater., 2020, 92, p 105315.

G. Singh, A Survey of Corrosivity of Underground Mine Waters From Indian Coal Mines, Int. J. Mine Water., 1986, 5, p 21–32.

M. Antonov, R. Veinthal, D.L. Yung, D. Katušin and I. Hussainova, Mapping of Impact-Abrasive Wear Performance of WC-Co Cemented Carbides, Wear, 2015, 332–333, p 971–978.

J. García, V. Collado Ciprés, A. Blomqvist, B. Kaplan, Cemented Carbide Microstructures: A Review, Int. J. Refract. Met. Hard Mater., 2019, 80, p 40–68.

S. Sutthiruangwong, G. Mori and R. Kösters, Passivity and Pseudopassivity of Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2005, 23, p 129–136.

G. Li, Y. Peng, L. Yan, T. Xu, J. Long and F. Luo, Effects of Cr Concentration on the Microstructure and Properties of WC-Ni Cemented Carbides, J. Mater. Res. Technol., 2020, 9, p 902–907.

A.G.P. Da Silva, C.P. De Souza, U.U. Gomes, F.F.P. Medeiros, C. Ciaravino and M. Roubin, Low Temperature Synthesized NbC as Grain Growth Inhibitor for WC-Co Composites, Mater. Sci. Eng. A., 2000, 293, p 242–246. https://doi.org/10.1016/S0921-5093(00)00993-X

D.S. Konadu, J. van der Merwe, J.H. Potgieter, S. Potgieter-Vermaak and C.N. Machio, The Corrosion Behaviour of WC-VC-Co Hardmetals in Acidic Media, Corros. Sci., 2010, 52, p 3118–3125.

I. Sugiyama, Y. Mizumukai, T. Taniuchi, K. Okada, F. Shirase, T. Tanase et al., Formation of (W, V)Cx Layers at the WC/Co Interfaces in the VC-Doped WC-Co Cemented Carbide, Int. J. Refract. Met. Hard Mater., 2012, 30, p 185–187.

C.N. Machio, D.S. Konadu, J.H. Potgieter, S. Potgieter-Vermaak, J. Van der Merwe, Corrosion of WC-VC-Co Hardmetal in Neutral Chloride Containing Media, ISRN Corros., (2013) 1–10

J. Weidow and H.O. Andrén, Grain and Phase Boundary Segregation in WC-Co with TiC, ZrC, NbC or TaC Additions, Int. J. Refract. Met. Hard Mater., 2011, 29, p 38–43.

S.H. Hayashi K, Fuke Y, , Effects of Addition Carbides on the Grain Size of WC– Co Alloy, J Jpn Soc. Powder Met., 1972, 19, p 67–71.

X. Ren, H. Miao and Z. Peng, A Review of Cemented Carbides for Rock Drilling: An Old But Still Tough Challenge in Geo-Engineering, Int. J. Refract. Met. Hard Mater., 2013, 39, p 61–77.

J. Kümmel, K. Poser, F. Zanger, J. Michna, V. Schulze, Surface Layer States of Worn Uncoated and TiN-Coated WC/Co-Cemented Carbide Cutting Tools After Dry Plain Turning of Carbon Steel, Adv. Tribol., 2013, 2013, p 519686.

W.D. Schubert, E. Lassner, W. Bohlke, Cemented carbides-a success story, Tungsten, International Tungsten Industry Association, (2010), p 1–12

J. Larsen-Basse, Wear of Hard-Metals in Rock Drilling: A Survey of the Literature, Powder Metall., 1973, 16, p 1–32.

X. Yang, X. Li and Y. Lu, Wear Characteristics of the Cemented Carbide Blades in Drilling Limestone With Water Jet, Int. J. Refract. Met. Hard Mater., 2011, 29, p 320–325.

A. C. A. de Melo, J. C. G. Milan, M. B. da Silva, Á. R. Machado, Some observations on wear and damages in cemented carbide tools, Journal of the Brazilian Society of Mechanical Sciences and Engineering, 2006, 28, p 269–277.

I. Konyashin, B. Ries, S. Hlawatschek and A. Mazilkin, Novel Industrial Hardmetals for Mining, Construction and Wear Applications, Int. J. Refract. Met. Hard Mater., 2018, 71, p 357–365.

J. Sun, J. Zhao, F. Gong, X. Ni and Z. Li, Development and Application of WC-Based Alloys Bonded with Alternative Binder Phase, Crit. Rev. Solid State Mater. Sci., 2019, 44, p 211–238.

A.K. Kasar, A. Siddaiah, R. Ramachandran and P.L. Menezes, Tribocorrosion Performance of Tool Steel for Rock Drilling Process, J. Bio- Tribo-Corrosion., 2019, 5, p 1–8.

E. Holmström, R. Lizárraga, D. Linder, A. Salmasi, W. Wang, B. Kaplan et al., High Entropy Alloys: Substituting for Cobalt in Cutting Edge Technology, Appl. Mater. Today., 2018, 12, p 322–329.

D.B. Miracle and O.N. Senkov, A critical review of high entropy alloys and related concepts, Acta Mater., 2017, 122, p 448–511.

W.J. Tomlinson and N.J. Ayerst, Anodic Polarization and Corrosion of WC-Co Hardmetals Containing Small Amounts of Cr3C2 and/or VC, J. Mater. Sci., 1989, 24, p 2348–2352.

A.K. Kasar, A. Siddaiah, R. Ramachandran and P.L. Menezes, Tribocorrosion Performance of Tool Steel for Rock Drilling Process, J. Bio-Tribo-Corrosion., 2019, 5, p 36–43.

G.N. Mekgwe, W.R. Tuckart, O.J. Akinribide, T. Langa, B.A. Obadele, P.A. Olubambi, Effect of CrC-Ni on the tribological behaviour of WC cemented carbide., IOP Conf. Ser. Mater. Sci. Eng., 499, 4th International Conference on Structural NanoComposites, Berlin, Germany, 2019

M. Habibi Rad, M. Ahmadian and M.A. Golozar, Investigation of the Corrosion Behavior of WC-FeAl-B Composites in Aqueous Media, Int. J. Refract. Met. Hard Mater, 2012, 35, p 62–69.

R.J.K. Wood, S. Herd and M.R. Thakare, A Critical Review of the Tribocorrosion of Cemented and Thermal Sprayed Tungsten Carbide, Tribol. Int., 2018, 119, p 491–509.

F.J.J. Kellner, H. Hildebrand and S. Virtanen, Effect of WC Grain Size on the Corrosion Behavior of WC-Co Based Hardmetals in Alkaline Solutions, Int. J. Refract. Met. Hard Mater., 2009, 27, p 806–812.

A.M. Human, B. Roebuck and H.E. Exner, Electrochemical Polarisation and Corrosion Behaviour of Cobalt and Co(W, C) Alloys in 1 N Sulphuric Acid, Mater. Sci. Eng. A., 1998, 241, p 202–210.

P.K. Katiyar, P.K. Singh, R. Singh and A.L. Kumar, Modes of Failure of Cemented Tungsten Carbide Tool Bits (WC/Co): A Study of Wear Parts, Int. J. Refract. Met. Hard Mater., 2016, 54, p 27–38.

VV Timonin; AS Smolentsev; I O Shakhtorin; NI Polushin; AI Laptev; AS Kushkhabiev, , Causes of Wear of PDC Bits and Ways of Improving Their Wear Resistance, IOP Publishing, IOP Conf. Ser. Earth Environ. Sci., 2017, p 53

Y.F. Zheng, G. Fargas, O. Lavigne, E. Roitero and L. Llanes, Corrosion-Induced Changes on Hertzian Contact Damage in Cemented Carbides, Int. J. Refract. Met. Hard Mater., 2020, 92, p 105334.

Z.Z. Fang, M.C. Koopman and H. Wang, Cemented Tungsten Carbide Hardmetal-An Introduction, Comprehensive Hard Mater., 2014 1, p 123–137 (2014)

P.K. Katiyar and N.S. Randhawa, Corrosion Behavior of WC-Co Tool Bits in Simulated (Concrete, Soil, and Mine) Solutions with and Without Chloride Additions, Int. J. Refract. Met. Hard Mater, 2019, 85, p 105062.

U. Beste, T. Hartzell, H. Engqvist and N. Axén, Surface Damage on Cemented Carbide Rock-Drill Buttons, Wear, 2001, 249, p 324–329.

U. Beste and S. Jacobson, Friction Between a Cemented Carbide Rock Drill Button and Different Rock Types, Wear, 2002, 253, p 1219–1221.

U. Beste, S. Jacobson and S. Hogmark, Rock Penetration into Cemented Carbide Drill Buttons During Rock Drilling, Wear, 2008, 264, p 1142–1151.

U. Beste and S. Jacobson, A New View of the Deterioration and Wear of WC/Co Cemented Carbide Rock Drill Buttons, Wear, 2008, 264, p 1129–1141.

U. Beste, E. Coronel and S. Jacobson, Wear Induced Material Modifications of Cemented Carbide Rock Drill Buttons, Int. J. Refract. Met. Hard Mater., 2006, 24, p 168–176.

R.K. Abbas, A Review on the Wear of Oil Drill Bits (Conventional and the State of the Art Approaches for Wear Reduction and Quantification), Eng. Fail. Anal., 2018, 90, p 554–584.

S. Hwang and H. Jang, Effects of Overused Top-hammer Drilling Bits, Insights Min. Sci. Technol. Buttons., 2019, 1, p 37–43.

S. Nahak, S. Dewangan, S. Chattopadhyaya, G. Krolczyk and S. Hloch, Discussion on Importance of Tungsten Carbide - Cobalt (Wc-Co) Cemented Carbide and its Critical Characterization for Wear Mechanisms Based on Mining Applications, Arch. Min. Sci., 2018, 63, p 229–246.

W.H. Gu, Y.S. Jeong, K. Kim, J.C. Kim, S.H. Son and S. Kim, Thermal Oxidation Behavior of WC-Co Hard Metal Machining Tool Tip Scraps, J. Mater. Process. Technol., 2012, 212, p 1250–1256.

J.E. Cho, S.Y. Hwang and K.Y. Kim, Corrosion Behavior of Thermal Sprayed WC Cermet Coatings Having Various Metallic Binders in Strong Acidic Environment, Surf. Coat. Technol., 2006, 200, p 2653–2662.

S. Olovsjö, R. Johanson, F. Falsafi, U. Bexell and M. Olsson, Surface Failure and Wear of Cemented Carbide Rock Drill Buttons-The Importance of Sample Preparation and Optimized Microscopy Settings, Wear, 2013, 302, p 1546–1554.

K.T. Kembaiyan and K. Keshavan, Combating Severe Fluid Erosion and Corrosion of Drill Bits Using Thermal Spray Coatings, Wear, 1995, 186–187, p 487–492.

M. Groppe, Capacity Planning, Sandvik Hard Mater., Annual Report, (2014)

S. Ndlovu, K. Durst and G. Mathias, Investigation of the Sliding Contact Properties of WC-Co Hard Metals Using Nanoscratch Testing, Wear, 2007, 263, p 1602–1609.

K.J. Swick, G.W. Stachowiak and A.W. Batchelor, Mechanism of Wear of Rotary-Percussive Drilling Bits and the Effect Of Rock Type on Wear, Tribol. Int., 1992, 25, p 83–88.

J. Larsen-Base, C.M. Perrot and P.M. Robinson, Abrasive Wear of Tungsten Carbide-Cobalt Composites. I. Rotary Drilling Tests, Mater. Sci. Eng., 1974, 13, p 93–100.

Y.S. Zhongjian Zhang, Xu. Tao, W. Peng, D. Chen and Y. Jiang, The Influence of pH on Thermal Fatigue Crack Propagation Behavior, Int. J. Refract. Met. Hard Mater., 2013, 40, p 14–18.

S. Ishihara, H. Shibata, T. Goshima and A.J. McEvily, Thermal Shock Induced Microcracking of Cermets and Cemented Carbides, Scr. Mater., 2005, 52, p 559–563.

A.J. Gant, M.G. Gee and A.T. May, The Evaluation of tribo-Corrosion Synergy for WC-Co Hardmetals in Low Stress Abrasion, Wear, 2004, 256, p 500–516.

S. Nahak, S. Dewangan and S. Chattopadhyaya, Discussion on Wear Phenomenain Cemented Carbide, Procedia Earth Planet. Sci., 2015, 11, p 284–293.

K. Jia and T.E. Fischer, Abrasion Resistance of Nanostructured and Conventional Cemented Carbides, Wear, 1996, 200, p 206–214.

D.G.F. O’Quigley, S. Luyckx and M.N. James, An empirical Ranking of a Wide Range of WC-Co Grades in Terms of Their Abrasion Resistance Measured by the ASTM Standard B 611–85 test, Int. J. Refract. Met. Hard Mater., 1997, 15, p 73–79.

K.P. Mingard, H.G. Jones, M.G. Gee, B. Roebuck and J.W. Nunn, In Situ Observation of Crack Growth in a WC-Co Hardmetal and Characterisation of Crack Growth Morphologies by EBSD, Int. J. Refract. Met. Hard Mater., 2013, 36, p 136–142.

S. Ndlovu, K. Durst and M. Göken, Investigation of the Sliding Contact Properties of WC-Co Hard Metals Using Nanoscratch Testing, Wear, 2007, 263, p 1602–1609.

Acknowledgements

Authors acknowledge Department of Materials Science and Engineering, NIT Hamirpur for extending the characterization facilities.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Katiyar, P.K., Maurya, R. & Singh, P.K. Failure Behavior of Cemented Tungsten Carbide Materials: A Case Study of Mining Drill Bits. J. of Materi Eng and Perform 30, 6090–6106 (2021). https://doi.org/10.1007/s11665-021-05829-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05829-7